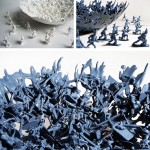

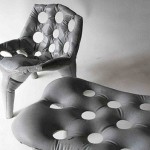

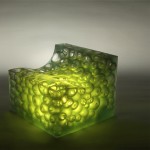

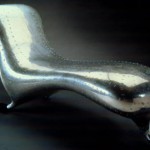

One of the most exciting endeavors for designers in any category is the chance to work with a completely new medium. By exploring the unique nature of a novel material, or employing a new manufacturing process to an existing material, new materials and processes bring the potential of incredibly unique aesthetics that are unachievable with the standard methods. Designers like Marc Newson delight in the Enabling Processes trend, with major manufacturing and materials companies seeking a creative opinion on what the latest innovative processes can achieve. These explorations are almost always conceptual and have very limited production quantities, as the goal is rarely to design a product for the mass-produced consumer market. However, the aesthetic possibilities these explorations open up have a highly influential effect on the broader design community as other designers seek ways to adapt these concepts for production using more standard methods. While this has long been the domain of the Fine Arts realm (think Jackson Pollock), lately the Furniture category has seen the most use of this theme, with designers exploring new processes to rethink the standard chair. Everything from cast quartz, to perforated metal sheets impacted by a falling mannequin, to cast concrete poured into structural membrane forms, to bent metal pillow forms have definitely pushed the envelope of what defines a chair. In the Consumer Electronics world, Apple has been incredibly inventive with scaling what were once prototyping processes (like the CNC-milled extrusions of the iPod Shuffle) into mass-production volumes, and achieving a quality of look and feel unmatched by traditional high-volume production methods. Our favorite example that crystallizes this trend: Dominic Wilcox’s Army Men bowls, created by melting toy army men into a simple bowl form. Classic familiar material paired with a simple production method to create something complete new and iconic, and unachievable with standard production methods. We believe there is just as much potential exploring a “low-tech” method as there is in the latest advanced materials, so a call to designers worldwide: reacquaint yourselves with classics processes like vacuum forming, shrink-wrapping, blow-molding, lathing, or casting, and overlooked materials like natural wood, concrete, plastic and metal sheet stock, chewing gum, and little rubber duckies.

Very timely post, there is a whole write-up in this month’s Wallpaper about this…you guys are at the forefront!

Soo cool. I really love this trend